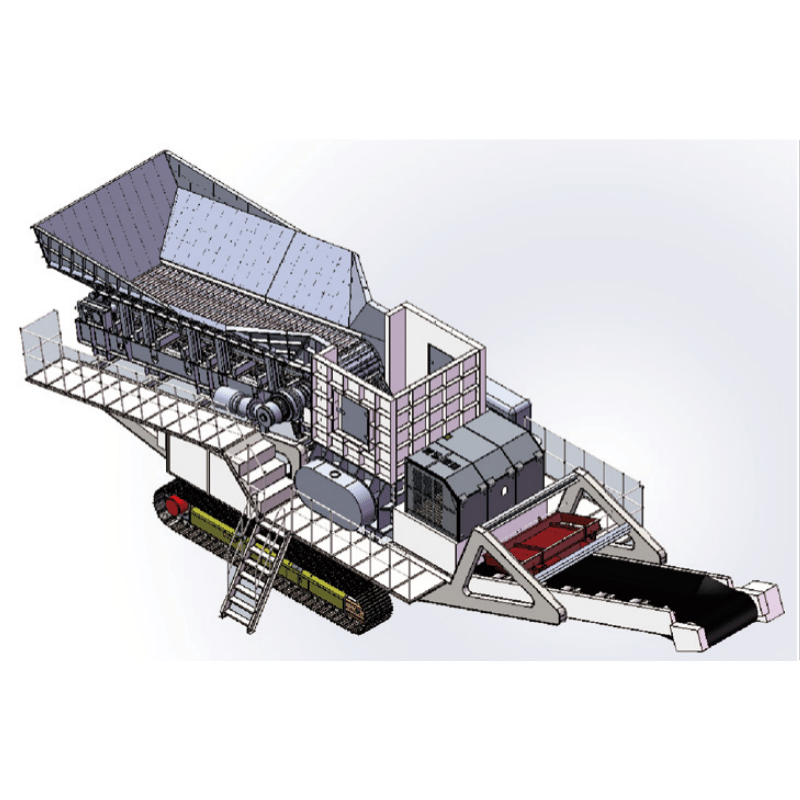

Mobile Stone Crushing and Screening Plant Jaw Crusher Crushing And Screening Machine

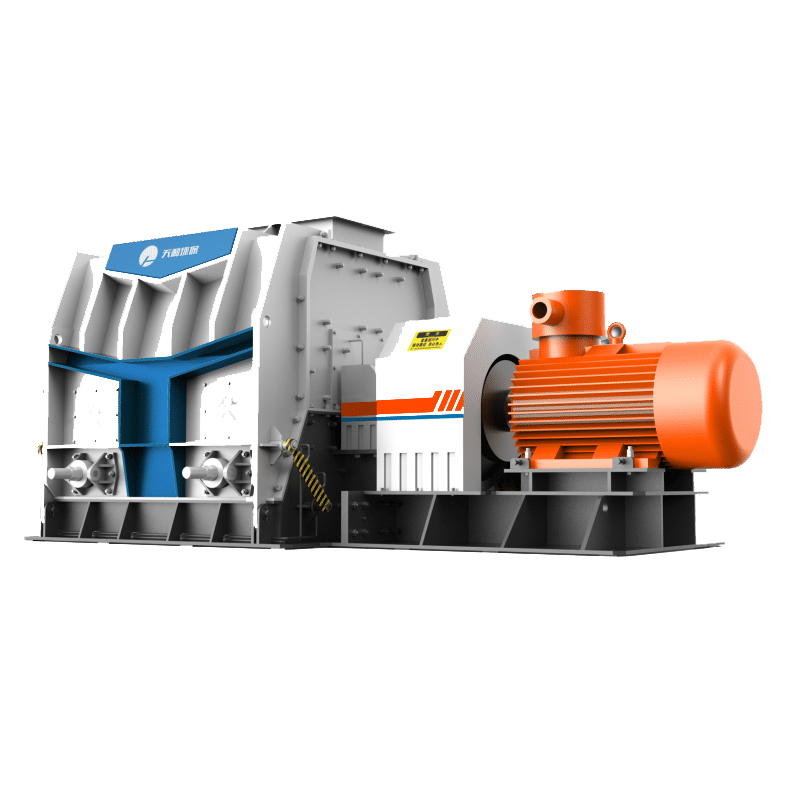

CRUSHING AND SCREEN MACHINE TECHNICAL FEATURES

◆ Compact structure and small volume, suitable for installation and use in underground tunnels

◆ Screening first, then crushing, the crusher has a large processing capacity and a high agglomeration rate

◆ The screen is made of wear-resistant material and has a long service life

◆ The material of the teeth of the toothed rollers is the bainitic wear-resistant alloy developed by our company, the hardness is HRC45~55, the impact toughness ak≥38kg•m/cm2, Integral alloy casting, high strength and wear resistance, strong impact resistance, long service life

◆ Crushing large pieces of raw coal and gangue, effectively protecting the belt along the trough, reducing transportation costs, prolonging the service life of the belt, and preventing chute blockage

|

MODEL |

FEEDING SIZE(mm) |

OUTPUT SIZE (mm) |

CAPACITY (t/h) |

POWER (kW) |

|

2PLF120150 |

≤1500 |

≤300 |

0-2000 |

220-450 |

|

2PLF120200 |

≤1500 |

≤300 |

0-4000 |

355-560 |

|

2PLF120300 |

≤1500 |

≤300 |

0-6000 |

450-710 |

|

2PLF150200 |

≤2000 |

≤350 |

0-5000 |

450-710 |

|

2PLF150300 |

≤2000 |

≤350 |

0-8000 |

630-900 |

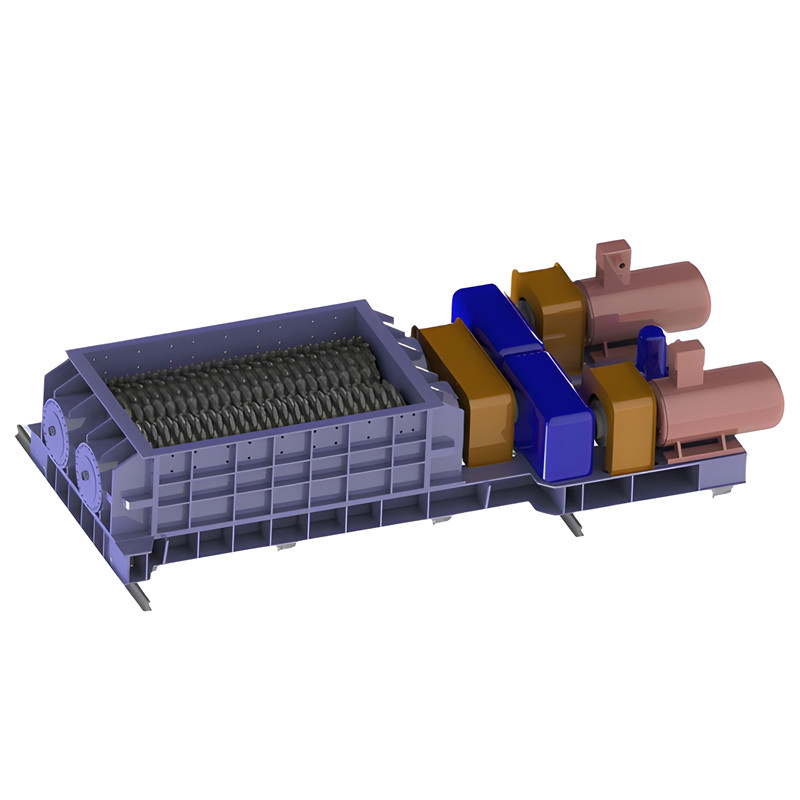

CRUSHING AND SCREEN MACHINE STRUCTURE

The main structure includes: roller screen module, crushing tooth roller module, drive module, mobile device, lubrication system. The roller screen module is composed of one or more groups of screening rollers, the rollers are arranged at an inclination angle, the screen is a triangle with arc transition, and the screening efficiency is high; Composition, the toothed roller adopts olecranon-type teeth, adopts the crushing principle of shearing and splitting, has strong biting ability, and effectively crushes mineral materials, improves the agglomeration rate and reduces the over-crushing rate; the drive module is driven by a frequency conversion motor, torque limiter The combination of reducer and reducer adopts cantilever structure, no installation frame, compact structure, and effectively reduces the volume of the equipment; walking device, the equipment is equipped with a walking device, which cooperates with the transfer scraper and moves on the self-moving tail of the belt conveyor; lubrication The system consists of a high-pressure plunger pump and an oil pipeline, which automatically fills the main lubrication points of the equipment with lubricating grease. This product has obtained coal safety certification.

INDUSTRY STATUS AND OBJECTIVES

With the development of underground coal mining technology in China, there are more and more coal mines with large mining height and large production capacity. In order to ensure the smooth production of coal mines, this kind of large-capacity screening and crushing integrated machine that crushes raw coal at the source of coal mining is required. Demand is growing. In line with this trend, our company has developed a screening and crushing integrated machine based on the profound technical reserves in the field of double-toothed roller crushers, which has been successfully put into market applications and has broad market prospects.

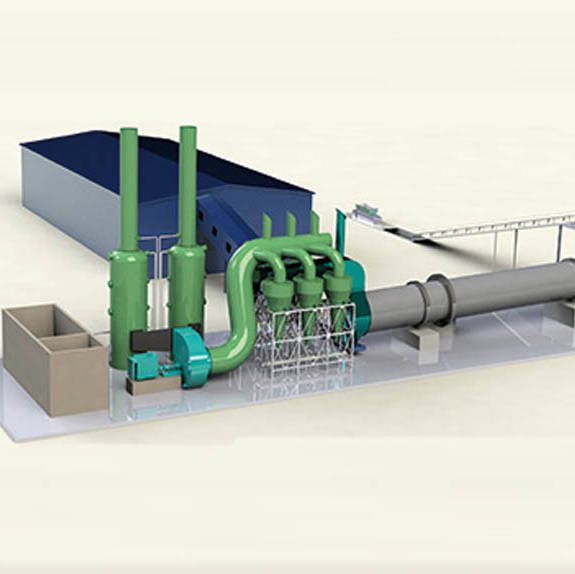

INSTALLATION STIE

Shaanxi Coal Caojiatan Mining Co., ltd.

1SET 2PLF120300

Inner Mongolia Erdos Yongmei Mining Investment Co., ltd.

1SET 2PLF120300